Weldability

Today we are talking to Laurent Lamps who manages Weldability within the heart of Olivier Revel’s team.

Laurent: tell us about your work-experience…

I hold a degree in mechanical and metallurgical engineering complemented by a degree in welding engineering. I joined Serimer in 1994 when the company had less than 100 people, I was lucky to see the company grow rapidly from a small French company to an international company. This period of growth gave me the opportunity to take various positions from welding engineer, project manager, deputy operation manager and to then of course gain the title of ‘expert’. I now look after the weldability issues at the Serimax WTC since 2015.

How many weldability tests has Serimax done since its creation in 1978?

This question is almost impossible to answer, we have worked on so many projects around the world on various types of metals. The company was created in 1978 and if I had to answer this question I would have to dig deep into the history! So I am sorry to say but I can’t answer this one…

What do you guarantee when completing a weldability test?

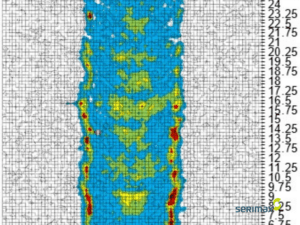

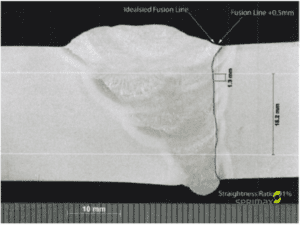

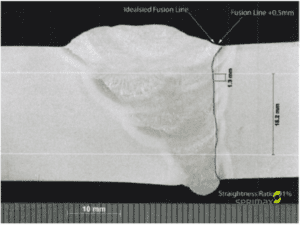

A weldability test is like a reduced welding procedure qualification focused on the Heat Affected Zone (HAZ). The HAZ is the base Material area where the mechanical properties are modified by the thermal cycle of the welding operation. We can call it a grey area as the mechanical properties are the results of the material alloying strategy and the welding strategy. A weldability test tests the HAZ under a specific welding strategy, this gives confidence to operators prior to needing costly specific welding procedure qualifications. It is also extremely important for a pipe manufacturer to assess their alloying strategies in ‘real’ welding conditions.

What do you actually do during a weldability test?

A weldability is a “small scale” welding procedure qualification therefore we follow the same processes as a welding procedure qualification.

- Welding Procedure Development

- “Official Welding”

- Welding Data Record

- Non-Destructive testing

- Mechanical Tests

- Hardness

- Charpy V Notch

- SSC Four Points Bend Test

- CTOD SENB

- Documentation

- Welding Book

- Weldability report

Have you managed weldability tests for all steel grades?

There is no limitation regarding the material type and material grade for the weldability tests at Serimax

- Carbon Steel (X52 to X100)

- Stainless Steel

- Clad material

On the pipe format, we have the same range as operational welding

- OD from 4.5″ to no limit

- WT from 6.5 to 55 mm and thicker

We can also work on plate.

We have access to all the welding processes / equipment available in the pipeline industry:

Manual / Semi-Automatic

- SMAW (cellulosic, low hydrogen)

- GTAW

- FCAW (all Filler Metal type)

Mechanized Welding

- mGMAW (all option possible)

- mGTAW (cold or hot wire)

Automatic Welding

- SAW

- Robotic welding

Is there one weldability program that covers all operational activities?

The answer is no.

There are various welding scenarios possible in operation that will impact the HAZ properties. They are mainly driven by:

- Welding Heat Input

- Welding position

- Line type (Flow Line / Fatigue Sensitive Line)

- Service condition (sweet / sour service)

We can see in the operator’s specifications and codes that the weldability is more and more an important topic with specific welding configuration (like the half V/J bevel) to be focused on the HAZ 100 %.

Common questions we get when talking about weldability

- Is my pipe weldable?

- What does it mean?

- Why are weldability tests important?

- What is a good weld?

- Is there one method to do a weldability test?

- What are the drivers for weldability?