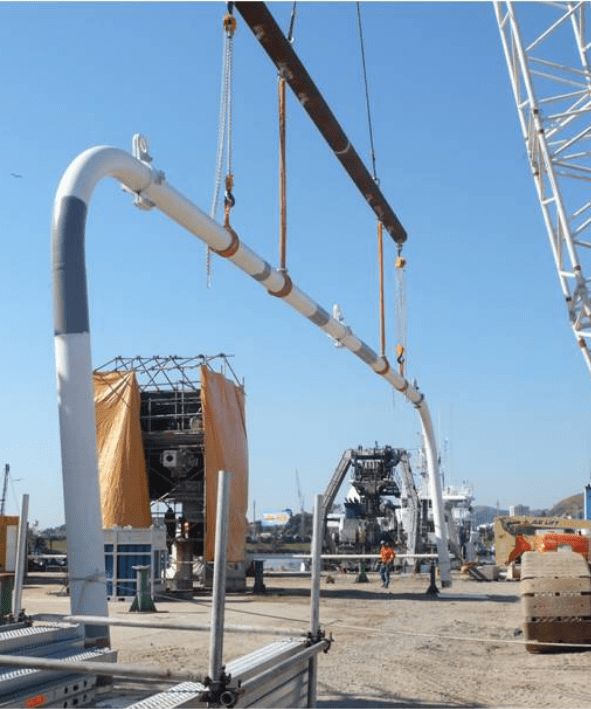

We specialize in high-end fabrication engineering for complex & challenging structures demanding stringent quality, dimensional control criteria.

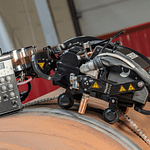

Previous expertise in delivering quality welding in challenging environments provides us with a competitive advantage for utility welding.

Saturnax 01 automatic welding never tires and offers pendular oscillation guaranteeing unlimited hours of quality welds.

Optimize your vessel schedule with welded structures delivered on time and get the job done right, first time!

- Near-field fabrication

- Subsea components

- Well jumpers and spool fabrication

- Multi-bore jumper assemblies

Welding secure waterlines, resistant to contamination. Whatever your needs are, our teams adapt quickly to meet your requirements.

- Trunk mains

- Aqueducts

- Waste line

- Sludge mains

- Spread welding

- Trench welding

- Project specific fabrication

One of our Project Track Records’ SPA can be found here!

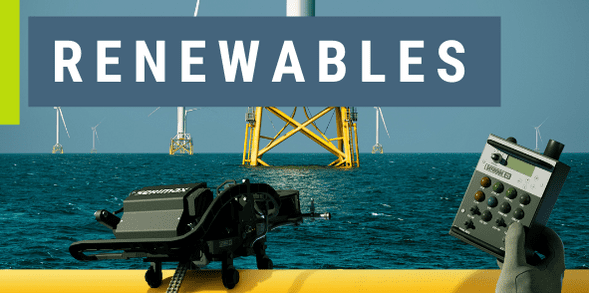

We embrace the energy transition and have developed welding solutions to manage the shift to greener energy, head on.

- Jacket welding

- Flange connections

- Hydrogen

- Floating wind

- Fixed wind

- Pumped Storage Hydro (PSH)

- Carbon Capture, Utilisation and Storage (CCUS)

Serimax is your reliable partner to deliver desired quality, on schedule all whilst meeting required welding specifications.

CONTACT US TO FIND OUT MORE

- 📍 HEAD OFFICE

- +33 1 56 48 90 50

- contact@serimax.com

- 📍 EUROPE, MIDDLE EAST, AFRICA, CIS, RUSSIA, KAZAKHSTAN

- +33 1 60 21 67 00

- 📍 NORTHERN EUROPE, THE UK AND SCANDINAVIA

- +44 1349 831 122

- 📍 NORTH & CENTRAL AMERICA

- +1 832 230 2700

- 📍 SOUTH AMERICA

- +55 21 2275 6033

- 📍 ASIA PACIFIC

- +603 2603 4555