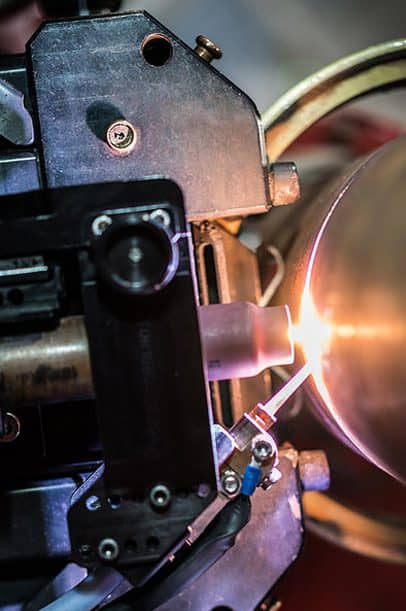

The SATURNAX bug & band welding system focuses on the golden rules of welding:

Designed for welders, by welders, Saturnax is known as the most stable automatic welding torch on the market and comes in 5 variants: 01, 07, 08 & 09.

DATASHEET

INTERNAX, the internal welding clamp with pipe rerounding capabilities supporting landline projects, offering:

The internax is dedicated to root pass welding for landline trunk line projects.

The SATURNE is the original fully-automated orbital welding system, and the fastest automatic welding system on the market.

Designed for trunklines, the Saturne operates 8 welding torches simultaneously to achieve world records in production.

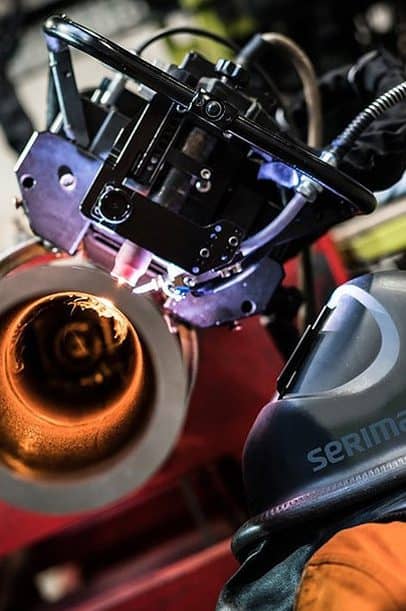

The EXTERNAX is Serimax’s automatic tie-in solution, offering:

The Externax can be part of a full-service offer: from mainline welding to spoolbase and offshore tie-ins.

The MULTINAX is Serimax’ solution dedicated to 1G pre-fabrication welding. It is a versatile, narrow gap GMAW assembly tool aiming to deliver high property standards for all diameters from 6″.

DATASHEET