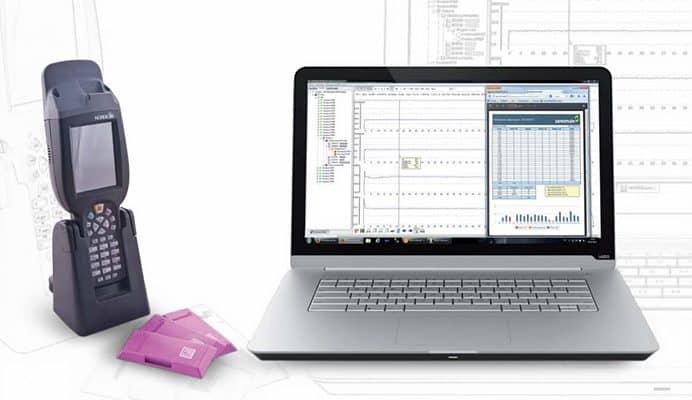

INTEGRITY

MANAGEMENT

CLEVERWELD

Serimax’ fully-automated integrity management solution designed for customizable, fit-for purpose pipeline production reporting, full traceability and data storage from anywhere in the world.

Full traceability on performance:

- Welding

- NDT, FJC

- Real-time production tracking

- Customizable reports

- Long-term data storage

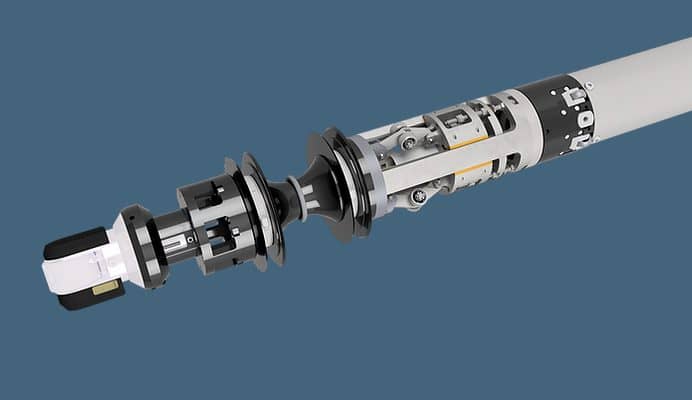

SCANVISION

Serimax’ digital solution for internal visual inspection measurement that documents your project welding DNA and creates trust in welding performance.

- Traceability and quality control

- Combines visual inspection and laser measurement

- Promotes firing line efficiency and saves time thanks to intermediate inspection capabilities

- Automatic profiling

- Calibrated video inspection

- For 12m / 24m pipe stalks and tie-ins at 1 km

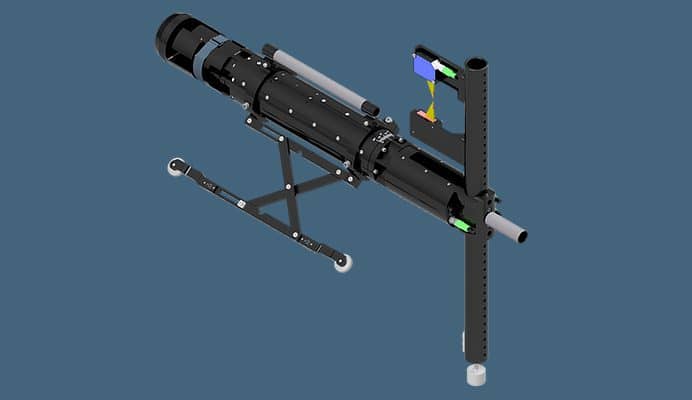

CLEVERSCAN

Serimax’ accurate and rapid measurement tool for pipe-end dimensions with pipe fit-up and sorting software suitable for pipemills, pipeyards, coating yard or offshore production sites projects.

- Improves weld quality

- Minimizes in fit-up time

- Increases productivity

- Optimizes pipe sorting

- Reduces downtimes

- Fulfil HiLo requirements

- Ability to measure the bevel

- Ensures integrity of welds

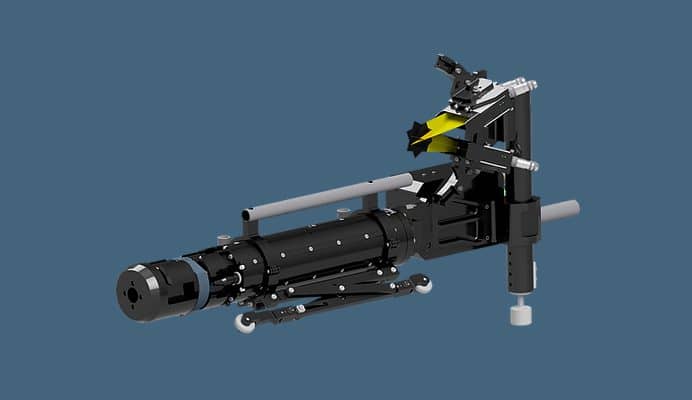

BEVELSCAN

Serimax’ accurate and rapid measurement tool for pipe-end dimensions or bevels with pipe sorting software. The equipment is suitable for CRA and SCR projects.

- Improves weld quality

- Increases productivity

- Optimizes HiLo

- Ensures integrity of welds

- Minimizes downtimes

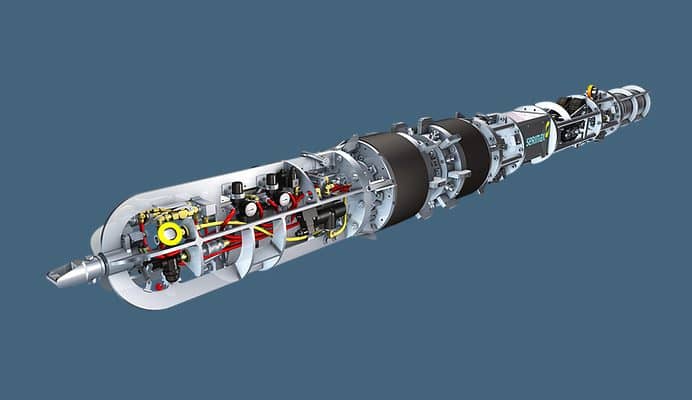

ROXANE

ROXANE Serimax’ ILUC fitted with Roxane gas purge module is a reliable line-up clamp providing the best solution for the welding of corrosion resistant alloy (CRA) materials.

- Ensures weld quality on CRA materials

- Full oxygen control with the ROXANE gas purge system

- Targeting all pipe diameters ranges